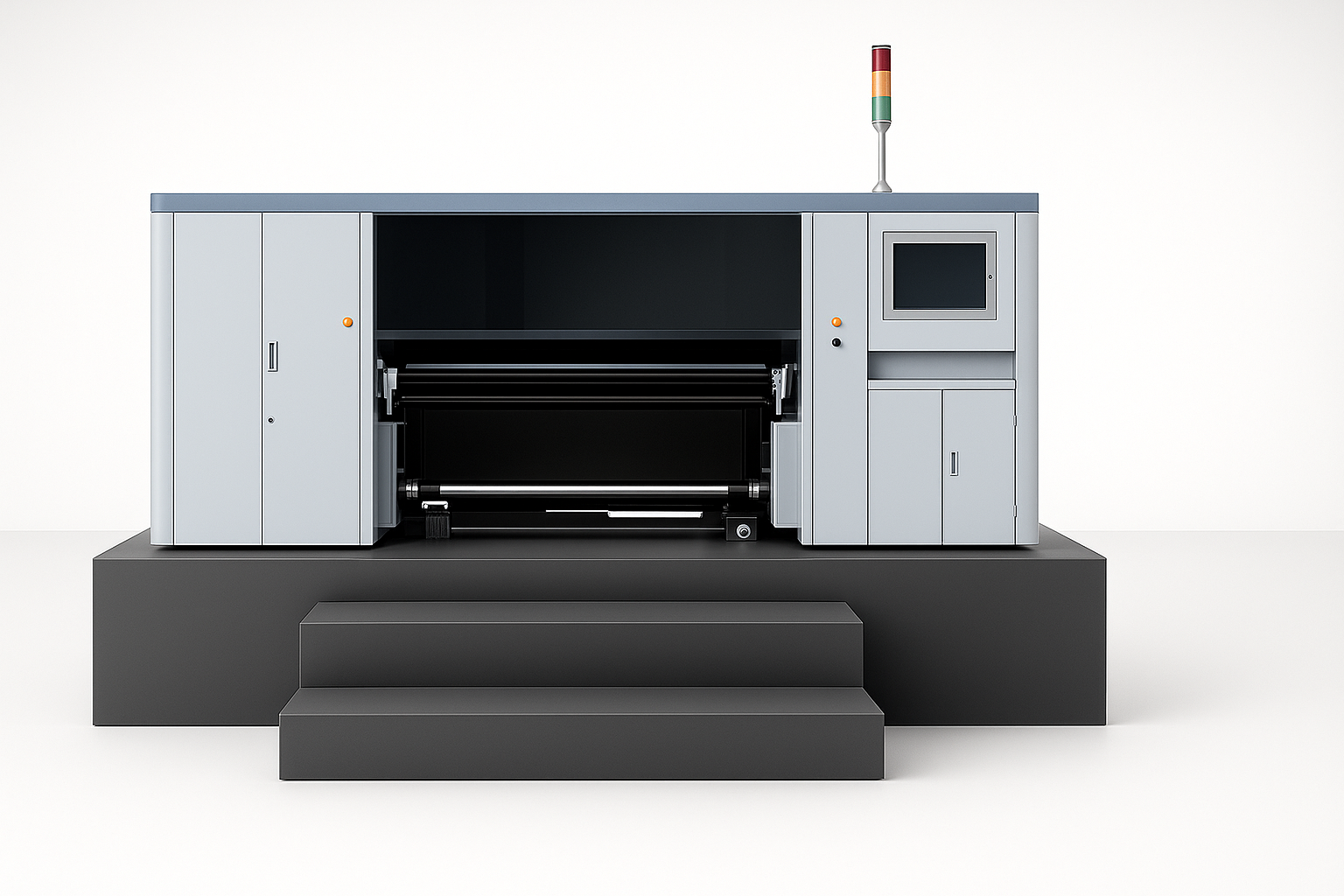

Engineered for performance

High-end digital printing

The Blaze from HGS Machines offers unsurpassed quality and value to textile printers who are taking the first step into digital production. It also offers a step up to high-performance, high-quality production for printers who wish to delelop their digital capabilities further.Blaze uses several printing modes and 16 or 32 Ricoh Gen 6 printheads with a resolution of 1200 & 600 dpi. Apart from ease, accuracy and productivity, Blaze offers flexibility and may be used with Reactive inks and different drying methods.

Save time, space and money

Digital printing has many benefits. It makes short-run, fast-turnaround jobs affordable for customers profitable for printers. It eliminates screen preparation time and makes more time available for printing full production runs on scren printing lines.

Multitude of applications

Open creative possibilities with the wide range of natural fabrics, both knitted as well as woven. Blotches and gradations can be printed with intense colors and smoothness thanks to the variable dropsize technology combined with the unique, unrivalled native 1200 dpi resolution.This also allows the printing of very fine lines and geometric designs that no other digital printer on the market can match.

A closer look to inspiring details

| Features | Description |

|---|---|

| Printing width | 1800 mm |

| No. of PH | 16 or 32 |

| Print heads | Ricoh Gen 6 |

| Ink | Reactive or Pigment |

| Colours | 8 |

| Environment Conditions | Room temperature 20 - 25°C |

| Printer Electronic | BYHX |

| Conveyor cleaning system | 3 Sponge roll, 1 brush roll, Back dryer, fabric supporting roll |

| Compressed Air | Consumption: 0.03m3/min Air pressure: 0.7Mpa |

| Print head gap | Up to 10 mm |

| Rip Supported | Neo Stampa |

| Power Supply & Electricity load | 16H - 26.8KW , 32H - 31.7KW (approx) |

| Print modes / Production modes | |||

|---|---|---|---|

| Blaze with 16H | |||

| Passes | DPI | Productivity (sq mtr) | |

| 1 | 600*600 | 220 | |

| 2 | 600*1200 | 130 | |

| Blaze with 32H | |||

| Passes | DPI | Productivity (sq mtr) | |

| 1 | 600*600 | 400 | |

| 2 | 600*1200 | 250 | |

* Actual performance may depend on the specific type of system and application settings.

The Blaze is a complete system, designed and engineered to make a complete solution. All elements are made to work together: printheads, inks, substrate conveyor, and dryer. With Blaze from HGS Machines, configuring the right combination for your requirements is possible without compromising results.

The Blaze comes standard with the Nova+Pro waveform, which ensures perfect drop positioning on the fabric for flawless image quality without striping. The Inline placement of printheads ensures no light-dark color effet in bloch color printing, increasing print speed while preventing the "Soccerfield effect." Additionally, this system extends printhead lifespan and minimizes issues like misaligned or missing nozzles, ensuring optimal printing results.

With HGS Machines you can access decades of experience in textile printing, right from the source. Our application support specialists are dedicated to help you explore new possibilities and will share everything there is to know to keep your Blaze in perfect condition. And when outstanding results matter, rely on HGS Machines ink technology. Our performance inks are specially formulated to deliver optimum performance. Our inks guarantee unattended printing without nozzle blockages or print head failures while adhering to the highest standards and legislation on sustainability

The right balance of technology incorporated in Blaze, internationally recognized inks and our full support ensures end-to-end control for consistent high-quality output. Whereas Blaze is built to control high speed and high quality in two different configurations. The Blaze with 16 printheads is a great option for entering in digital printing, where the Blaze with 32 printheads is the preferred choice for high volume printing. A Blaze can be later upgraded at the customer site from 16 to 32 printheads. The combination of RICOH GEN 6 print heads, Ink recercullation, chilling plant and our specially formulated performance inks ensures excellent runnability and longer print head lifetime. Most importantly, you can count on strong and vivid colours at the lowest possible ink consumption.